En abril 30º Rich Packing ha completado con éxito la preparación y carga segura de un sistema totalmente integrado Línea de producción de conteo y embotellado 16C , encargado por un cliente jordano hace tan solo 20 días. El contenedor, meticulosamente embalado y reforzado por nuestro equipo de logística experto, se cargó con éxito hoy, marcando otro hito en nuestra misión de ofrecer soluciones de ingeniería de precisión con un cuidado y una fiabilidad inigualables.

En profundidad: Línea de producción de conteo y embotellado de 16C

Este cliente jordano trabaja en la industria de la producción de suplementos, que utiliza con frecuencia la tecnología de conteo y embotellado. Hace unos 20 días, visitó nuestra fábrica y decidió incorporar nuestra línea de producción de 16 máquinas de conteo y embotellado para su producción de suplementos.

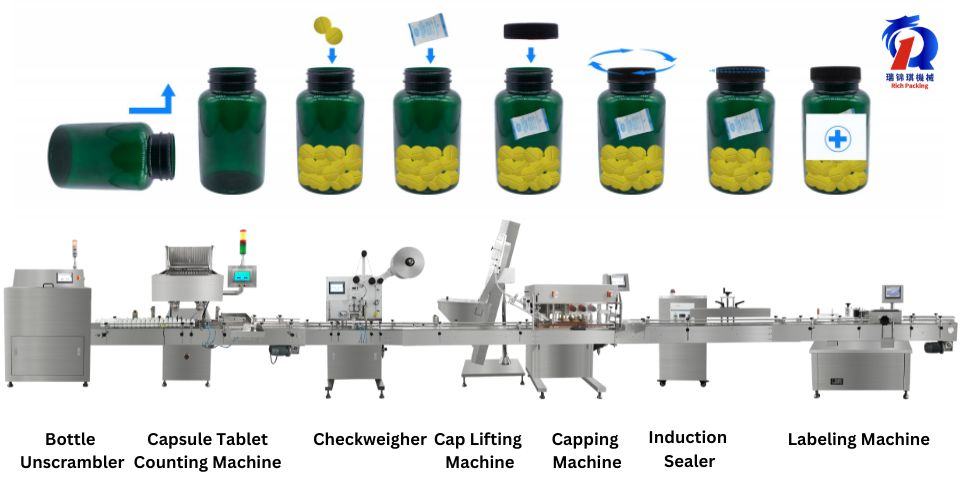

Este sistema llave en mano está diseñado específicamente para el envasado de alta velocidad de productos farmacéuticos y nutracéuticos, combinando a la perfección la automatización con una precisión excepcional. Las máquinas clave de la línea incluyen:

• Posicionador de botellas: clasifica y alimenta automáticamente las botellas vacías en la cinta transportadora, eliminando los cuellos de botella causados por la manipulación manual.

• Máquina contadora de tabletas/cápsulas: Adopta sensores fotoeléctricos avanzados y paneles de vibración de 3 etapas para garantizar una precisión de conteo del 99,98 %.

• Controlador de peso: verifica y rechaza instantáneamente las botellas con un llenado insuficiente o excesivo para mejorar la precisión estricta.

• Máquina tapadora y sistema de elevación de tapas: tapado hermético sin rayones, mientras que el elevador de tapas asegura un suministro ininterrumpido de tapas.

• Sellador por inducción: el sistema de conmutación de 2 modos se adapta a diferentes especificaciones de botellas y también proporciona sellos de aluminio herméticos.

• Etiquetadora: Sistema de alta precisión capaz de imprimir con claridad números de lote, fechas de producción, etc.

Al funcionar como una unidad sincronizada, la línea puede procesar hasta 70 botellas por minuto, lo que reduce considerablemente los costos de mano de obra y minimiza los errores humanos, garantizando así una producción fluida, eficiente y conforme a las normas para nuestro cliente. "¡Totalmente automatizada, de alta eficiencia y precisión, y a un precio razonable! ¡Es justo lo que buscábamos!", comentó el cliente durante la primera visita.

Excelencia en el embalaje: protocolos estándar y refuerzos personalizados

Para garantizar una entrega segura por transporte marítimo, implementamos una estrategia de embalaje de dos niveles:

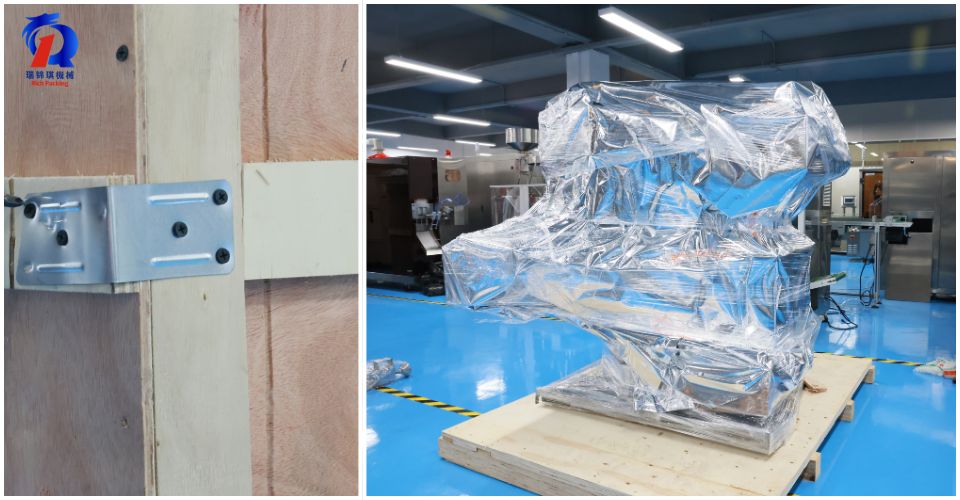

1. Embalaje estándar (protección básica):

• Cajas de madera sólida mejoradas: construidas con madera contrachapada de 10 mm de espesor para soportar firmemente cada máquina.

• Envoltura de Plástico + Sellado al Vacío: Envoltura de plástico impermeable de tres capas, combinada con envasado al vacío para evitar la humedad y la corrosión.

• Espuma anticolisión: evita impactos y daños causados por las turbulencias del mar durante el transporte de larga distancia.

• Protectores de esquinas mejorados: Las esquinas reforzadas con acero absorben los impactos durante el manejo durante el tránsito.

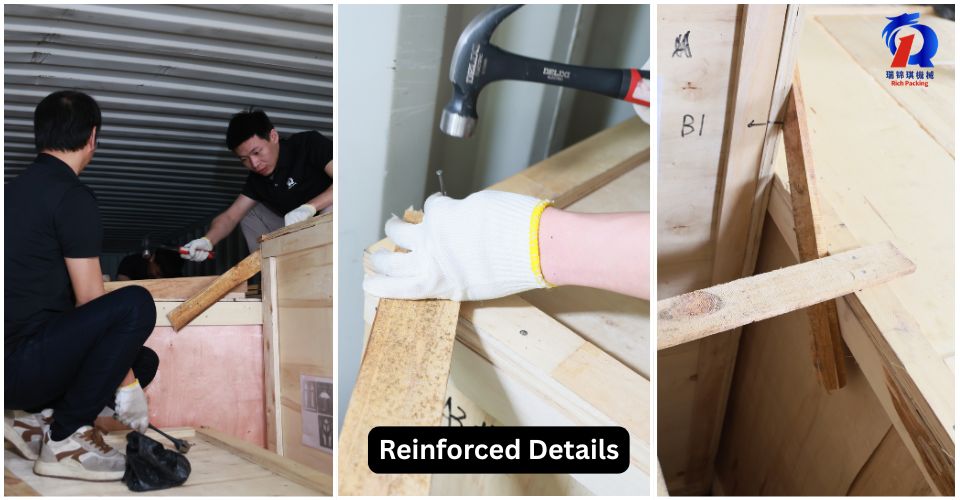

Al comprender los riesgos específicos del envío a larga distancia, fuimos más allá:

• Ingreso al contenedor y refuerzo manual: Nuestro equipo ingresó al contenedor para instalar manualmente tablones de madera de alta resistencia, fijando cada caja de forma segura a las paredes y al piso del contenedor utilizando clavos de grado industrial.

• Inspección final: cada caja fue sometida a pruebas de estrés físico para confirmar su total inmovilidad antes del sellado final del contenedor.

"Tratamos cada contenedor como un rompecabezas gigante", dijo nuestro Gerente de Logística. "Al martillar una rejilla de tablones a medida, evitamos incluso el más mínimo movimiento. Este enfoque es la razón por la que nuestros clientes confían en nosotros para una entrega global segura".

En Rich Packing, cada envío representa más que solo máquinas; es la confianza que nuestros clientes depositan en nosotros. Seguiremos enfocándonos en lo más importante: ayudar a nuestros socios globales a crecer con soluciones confiables y de alta calidad.