Como líder innovador en el campo de la maquinaria de envasado de productos farmacéuticos y de atención médica, Rich Packing anunció hoy el lanzamiento de la nueva Máquina llenadora de cápsulas líquidas completamente automática NJY-330C El equipo está diseñado para resolver los problemas de la industria del llenado de ingredientes líquidos, logrando un llenado ultrapreciso de ±0,1 ml, compatible con líquidos aceitosos, suspensiones y otros materiales difíciles, y brindando a los clientes globales una solución integral para el llenado de líquidos en cápsulas.

La máquina llenadora de cápsulas líquidas NJY-330C es apta para cápsulas de todas las especificaciones, desde la n.° 000 hasta la n.° 3, satisfaciendo así las necesidades de producción de productos sanitarios y farmacéuticos. Puede equiparse con módulos de llenado de microgránulos y cápsulas pequeñas de doble material, que admiten:

✅ Relleno de líquido puro

✅ Relleno compuesto de micropellets + líquido

✅ Llenado de líquido de cápsulas pequeñas anidadas (diferencia de tamaño recomendada de 2, como 0 cápsulas con 2 cápsulas pequeñas)

✅ El sistema de disco de dosis personalizado controla con precisión el volumen de llenado de líquido

La máquina de cápsulas líquidas farmacéuticas adopta el sistema de bomba de cerámica accionado por servomotor doble Schneider (motor de llenado + motor de succión trasera).

La máquina de llenado de cápsulas de líquido totalmente automática controla el flujo de líquido en un circuito cerrado, con una precisión de llenado de >99%, logrando el estándar líder en la industria de "cero fugas".

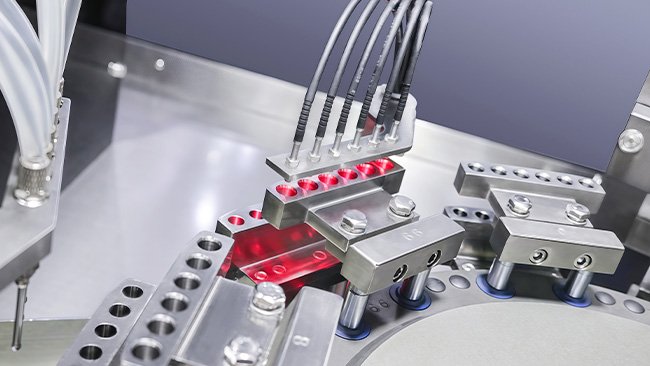

La máquina de cápsulas líquidas de Rich Packing está equipada con un exclusivo sistema de detección de fibra óptica de alta precisión para monitorear el estado de separación de la tapa de la cápsula en tiempo real.

A diferencia de la máquina llenadora de cápsulas de gránulos de polvo, NJY-330C fue pionera en el "dispositivo de rechazo de desechos de succión superior de doble etapa": las cápsulas no separadas primero se levantan y luego se adsorben negativamente para lograr el rechazo general de la tapa de la cápsula y la tasa de eliminación alcanza el 100%.

La máquina llenadora de líquido con cápsulas duras utiliza todos los componentes principales importados: controlador Siemens, cojinetes ABB, componentes eléctricos Schneider, bomba de vacío Baker y el tiempo medio entre fallos (MTBF) supera las 35.000 horas.

Sistema inteligente en línea de la máquina llenadora de cápsulas líquidas: el canal de transmisión de cápsulas está equipado con puntos de detección duales (cápsula llena/cápsula faltante) y la velocidad del rodillo de la máquina selladora de cápsulas se ajusta automáticamente para garantizar la suavidad de todo el proceso de llenado de cápsulas.

Tecnología de secado por aire vertical: los ventiladores dobles superiores e inferiores funcionan en tres dimensiones, secado con viento fuerte en la parte superior + enfriamiento rápido en la parte inferior, acortando el ciclo del proceso de llenado de la cápsula líquida en un 37%.

Basándose en la experiencia en la cadena de suministro de las 500 empresas más importantes del mundo, Rich Packing ofrece un conjunto completo de soluciones de máquinas de llenado de cápsulas:

✅ Planificación de líneas de producción de plantas cGMP

✅ Soporte transfronterizo para instalación y puesta en marcha en sitio

✅ Capacitación completa del proceso para operadores

✅ Servicios de consultoría técnica de por vida

"La máquina llenadora de cápsulas totalmente automática NJY-330C redefine el estándar de precisión en la producción de cápsulas líquidas", afirmó el Sr. Yang, director técnico de Rich Packing. "No solo solucionamos el problema de las fugas de líquido en la industria, sino que también ayudamos a los clientes a responder con flexibilidad a las diversas necesidades de desarrollo de productos gracias a su diseño modular".

La máquina llenadora de líquidos con cápsulas duras ya está disponible para preordenar. Bienvenidos a visitarnos. Sitio web oficial de Rich Packing para obtener documentos técnicos y soluciones personalizadas.