En la fabricación de comprimidos, la molienda y la granulación de la materia prima antes del tableteado son pasos clave para determinar la calidad y la consistencia de los comprimidos. Dominar el uso de estos procesos y sus equipos no solo puede mejorar la eficiencia de prensado de tabletas producción, sino también garantizar la estabilidad y seguridad del producto final. Este artículo explicará en detalle los aspectos importantes de los procesos de molienda y granulación y brindará recomendaciones para equipos relacionados.

La trituración y la granulación son pasos críticos en el proceso de fabricación de comprimidos, ya que determinan la calidad del comprimido final y la eficiencia del proceso de tableteado. En la industria farmacéutica, es necesario procesar partículas grandes o trozos de material en gránulos aptos para tableteado. El tamaño y la forma adecuados de los gránulos pueden mejorar eficazmente la fluidez y la compresibilidad de los comprimidos, garantizar un tableteado fluido y proporcionar a los comprimidos terminados un peso, una dureza y un tiempo de desintegración constantes. Por ejemplo, los gránulos demasiado grandes pueden provocar una dureza desigual de los comprimidos durante el proceso de compresión, mientras que los gránulos demasiado pequeños pueden afectar su disolución. Por lo tanto, optimizar los pasos de trituración y granulación no solo contribuye a mejorar la productividad, sino que también garantiza una calidad constante del producto.

La pulverización es el proceso de procesar materias primas de gran tamaño en partículas finas o polvos para su posterior granulación y tableteado. Al seleccionar el equipo de pulverización, se deben considerar la dureza, el contenido de humedad y las propiedades físicas de la materia prima para garantizar la uniformidad y el flujo de los gránulos finales. A continuación, se presentan algunos tipos comunes de equipos de pulverización y sus aplicaciones.

Clasificación y escenarios de aplicación de los equipos pulverizadores:

|

Tipo de dispositivo |

Escenario de aplicación |

Ventaja |

Defecto |

|

Molino de aire |

Materiales sensibles a la temperatura que requieren procesamiento a baja temperatura |

Alta velocidad, sin contaminación. |

Mal efecto sobre materiales duros |

|

Molino de alta eficiencia |

Materias primas de gran volumen y alta dureza. |

Rápido, eficiente y adaptable |

Manipulación limitada de materiales sensibles al calor |

|

Molino de martillos |

Adecuado para materiales medianamente duros y quebradizos como hierbas y materiales vegetales secos. |

Fácil de operar, bajo costo. |

No apto para pulverización ultrafina, alto nivel de ruido. |

|

molino de bolas |

Adecuado para pulverización ultrafina, como rotura de células y nanomateriales. |

Finura ultraalta |

Alto consumo de energía y largo tiempo de pulverización. |

Molino de martillos: Es un equipo de pulverización común, ampliamente utilizado para pulverizar materiales de dureza media y frágiles, como hierbas, minerales y materiales vegetales secos. Impacta el material mediante martillos rotatorios de alta velocidad para la trituración inicial y controla el tamaño del material triturado mediante una criba. Las principales ventajas del molino de martillos son su estructura simple, bajo costo y amplia adaptabilidad, especialmente utilizado en plantas farmacéuticas y laboratorios pequeños y medianos. Sin embargo, debe tenerse en cuenta que el molino de martillos puede tener un rendimiento deficiente al manipular polvos particularmente finos o materiales que requieren un control de alta precisión. Además, es ruidoso durante el funcionamiento y requiere un control adecuado del ruido en el entorno operativo.

El proceso de granulación húmeda se utiliza para formar gránulos mezclando polvos y aglutinantes líquidos para mejorar el flujo y la compresibilidad de los gránulos y para garantizar la estabilidad del proceso de formación de comprimidos posterior. Este proceso se utiliza ampliamente en la industria farmacéutica y es particularmente adecuado para productos que requieren un alto grado de firmeza y homogeneidad de los gránulos.

Clasificación y aplicación de equipos de granulación húmeda:

|

Tipo de dispositivo |

Escenario de aplicación |

Ventaja |

|

Granulador de lecho fluidizado |

Adecuado para el tratamiento de materias primas sensibles al calor. |

Uniformidad de partículas Alta uniformidad de partículas, Adecuado para producción en masa |

|

Granulador mezclador |

Adecuado para granulación rápida y producción en masa. |

Fácil de operar, adecuado para producción de lotes pequeños. |

|

Granulador rotatorio |

Adecuado para materiales muy viscosos, partículas uniformes. |

El efecto de granulación de los materiales viscosos es bueno y el control del tamaño de partícula es más preciso. |

El granulador de lecho fluidizado forma gránulos suspendiendo el polvo en una corriente de aire mientras se pulveriza un aglutinante líquido. Es adecuado para la manipulación de materiales sensibles al calor y garantiza la homogeneidad y consistencia de los gránulos. Se utiliza comúnmente en las industrias farmacéutica, alimentaria y otras que requieren gránulos de alta calidad.

Ventajas del granulador de agitación húmeda:

El principio de funcionamiento del granulador con agitación consiste en mezclar el polvo y el aglutinante líquido mediante agitación mecánica para obtener gránulos uniformemente. El granulador con agitación es fácil de operar, especialmente adecuado para la producción de lotes pequeños y medianos. La velocidad de mezcla y la dosis de aglutinante se pueden ajustar según las características de los diferentes materiales para lograr un control más preciso de los gránulos. En comparación con los granuladores de lecho fluidizado, los granuladores con agitación son más económicos y adecuados para entornos de producción con presupuestos limitados.

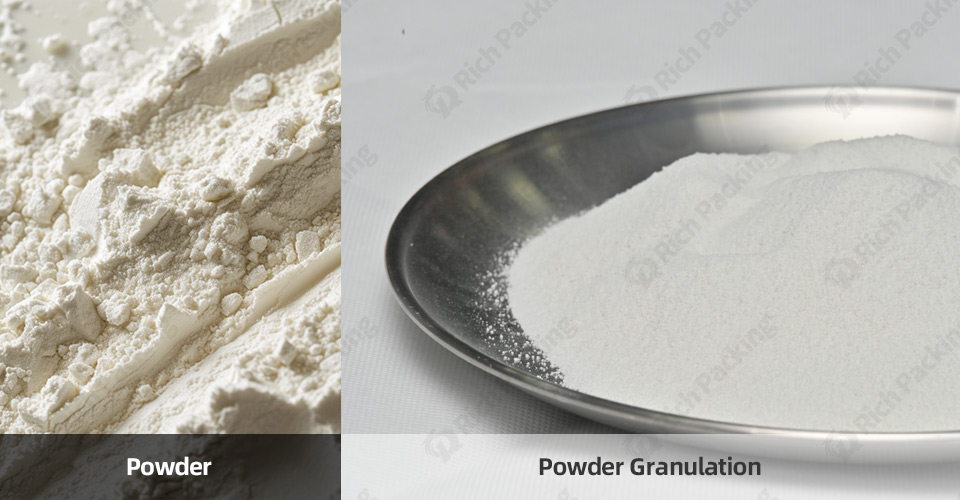

La granulación seca forma partículas comprimiendo directamente el polvo sin añadir un aglutinante líquido. Es especialmente adecuada para materiales que no son aptos para el contacto con líquidos, como algunos ingredientes activos que son fácilmente delicuescentes, termosensibles o inestables. En comparación con la granulación húmeda, la granulación seca elimina el paso de secado y puede reducir significativamente el consumo de energía y el tiempo.

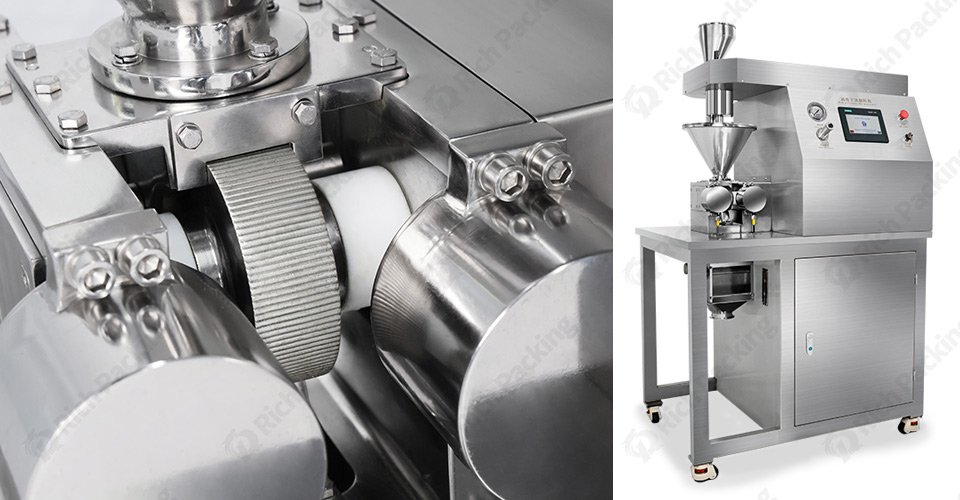

Granulador en seco por compresión de rodillos: El polvo se comprime en copos mediante la presión entre dos rodillos de presión, que posteriormente se trituran y tamizan para formar gránulos. La ventaja es que no requiere aglutinante líquido, lo que lo hace especialmente adecuado para materias primas no aptas para el procesamiento en húmedo. Además, la granulación en seco puede reducir significativamente el consumo de energía, ya que se elimina el paso de secado posterior.

Durante la granulación en seco, es necesario asegurar que la materia prima sea suficientemente compresible; de lo contrario, podría producirse una formación deficiente de pellets o una densidad desigual. Este método suele ser adecuado cuando se trabaja con principios activos farmacéuticos sensibles a la humedad o cuando se requiere una producción rápida.

El tamaño y la homogeneidad de las partículas son fundamentales para la calidad de las tabletas prensadas. Las partículas excesivamente grandes o pequeñas afectan la fluidez y la compresibilidad de las tabletas prensadas, lo que a su vez afecta la dureza y la solubilidad del producto final, así como la liberación del efecto del fármaco. Controlar el tamaño de las partículas durante el proceso de trituración y granulación es fundamental para garantizar la consistencia de las tabletas.

Puede elegir diferentes equipos de pulverización y procesos de granulación para distintos medicamentos y necesidades de producción. Por ejemplo, la pulverización fina garantiza una mejor uniformidad de las partículas, mientras que la granulación húmeda mejora su compresión. Independientemente del equipo utilizado, es fundamental garantizar que los pellets tengan el tamaño adecuado y cumplan con los estándares de producción.

La elección del equipo depende del tamaño de la producción, las características de la materia prima y los requisitos de producción. Si trabaja con materiales sensibles a la temperatura o necesita un control de alta precisión, los pulverizadores de flujo de aire y los granuladores de lecho fluidizado pueden ser una mejor opción. Por otro lado, para procesar grandes cantidades de materiales de dureza media, los molinos de martillos y los granuladores con agitador son soluciones más rentables.

Además, el cumplimiento de las BPM del equipo, el grado de automatización y el coste de mantenimiento son factores clave a considerar. Al seleccionar el equipo, es fundamental asegurarse de que satisfaga sus necesidades de producción y los requisitos normativos.

La molienda y la granulación son pasos cruciales en la producción de tabletas que no pueden ignorarse. Al elegir el equipo y el proceso adecuados, puede aumentar la productividad y garantizar la consistencia y altos estándares de calidad para su producto. Comprender y dominar los detalles de estos procesos le ayudará a alcanzar un mayor éxito en la fabricación de tabletas.