A medida que las industrias farmacéutica y nutracéutica global continúan avanzando, los estándares para evaluar la maquinaria de envasado han evolucionado drásticamente. Atrás quedaron los días en que los compradores se centraban únicamente en la velocidad, la precisión o la calidad del material. Hoy en día, lo que realmente determina el valor de una máquina llenadora de cápsulas, línea de conteo de gomitas , o una máquina prensadora de tabletas Hay algo mucho menos visible, pero mucho más crítico: la calidad, la accesibilidad y la profesionalidad del servicio posventa.

Para muchos fabricantes internacionales, el equipo no es una simple compra única, sino una colaboración continua. Las máquinas requieren instalación, calibración, mantenimiento y, a veces, resolución de problemas complejos. Y en entornos transfronterizos donde el idioma, la distancia y las diferencias horarias plantean desafíos, un soporte confiable se convierte en la base de la continuidad operativa.

Reconociendo estas necesidades globales, Rich Packing Machinery ha desarrollado un sistema integral de servicio posventa adaptado a usuarios internacionales. Mediante una combinación de accesibilidad 24/7, videoinstrucciones personalizadas, puesta en marcha remota, un equipo de ingeniería especializado y una garantía de tres años, la empresa está redefiniendo el concepto de soporte confiable en la industria de la maquinaria de envasado.

Este cambio se vuelve aún más significativo cuando examinamos las tendencias reales que ocurren en el mercado global.

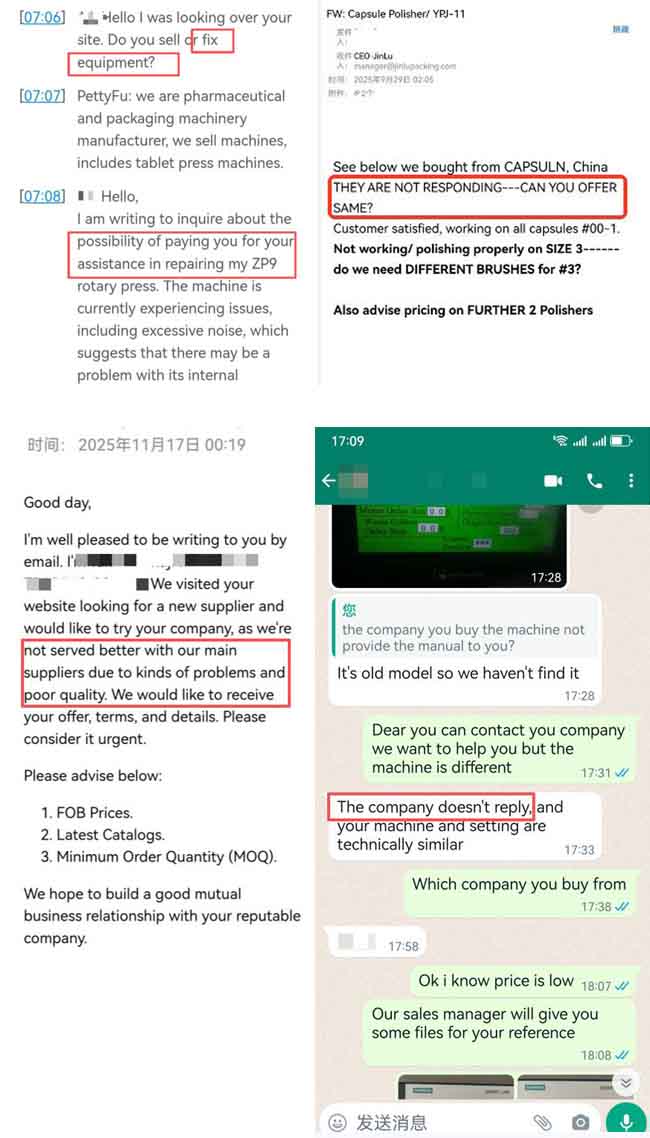

Uno de los desarrollos más inesperados de los últimos años es el creciente número de consultas que Rich Packing recibe de fábricas que no adquirieron nuestras máquinas. Estos fabricantes poseen equipos de otros proveedores: a veces encapsuladoras, a veces líneas de conteo automático, a veces... rellenos en polvo —pero su motivo para contactarnos es siempre el mismo: No pueden comunicarse con su proveedor original o no pueden resolver los problemas rápidamente.

Realmente nos pasan muchas cosas así. Muchos describen situaciones como:

“Necesitamos cambiar los modelos de cápsulas y el proveedor no responde”.

“La línea de conteo no se sincroniza con la cinta transportadora y nadie responde a nuestros correos electrónicos”.

“Nos dijeron que la instalación es 'sencilla', pero no logramos calibrar correctamente la máquina llenadora de cápsulas”.

“Las alarmas de la máquina siguen apareciendo y el proveedor está al otro lado del mundo”.

Este patrón revela una clara brecha de servicio en la industria. También demuestra por qué la reputación de confiabilidad y accesibilidad de Rich Packing ha trascendido con creces a su base de clientes directos.

Más importante aún, esta tendencia conduce naturalmente a la pregunta: ¿Qué hace que Rich Packing sea diferente y por qué más fábricas en el extranjero eligen nuestro apoyo?

Para abordar los desafíos que enfrentan los clientes internacionales, Rich Packing basó su modelo de servicio en cuatro pilares esenciales. Estos componentes se combinan para garantizar que los clientes reciban un soporte rápido, preciso y continuo desde la llegada de su equipo.

En muchos mercados, la mayor frustración es simplemente no saber a quién llamar. Rich Packing elimina esta incertidumbre por completo.

Cada máquina llenadora de cápsulas La línea de conteo de gomitas, la línea de llenado de botellas y el sistema de llenado de polvo se entregan con:

◉ Nombre completo del vendedor responsable

◉ Su número directo de WhatsApp

◉ Una línea directa de servicio 24 horas al día, 7 días a la semana

◉ Manuales de instrucciones y vídeos

◉ Contacto del sitio web oficial de la empresa

Esto garantiza que, independientemente de si el cliente se encuentra en Los Ángeles, Dubái, Singapur o Varsovia, nunca se encontrará con un momento en el que no pueda contactar con nadie. Los operadores pueden enviar videos, fotos o mensajes de voz, y los ingenieros responden de inmediato.

Esta accesibilidad personalizada mejora naturalmente la eficacia de la protección a largo plazo ofrecida a los clientes.

A diferencia de los proveedores de equipos típicos que ofrecen garantías de un año, Rich Packing ofrece una garantía de tres años en todas las máquinas, ya sea una máquina llenadora de cápsulas de alta velocidad, una línea de conteo de gomitas con diseño personalizado o una máquina prensadora de tabletas completamente automática.

Esto ofrece a los clientes:

Menor riesgo operativo

Mayor confianza durante la producción continua

Reducción de los costes de mantenimiento a largo plazo

Además, la El primer año incluye reemplazo gratuito de piezas de desgaste. , lo que permite a los clientes estabilizar la producción sin preocuparse por obtener piezas a nivel internacional.

Naturalmente, la protección a largo plazo solo es valiosa cuando se combina con una sólida capacidad técnica, y eso nos lleva directamente a nuestro próximo pilar.

El servicio posventa de Rich Packing está a cargo de un equipo de ingenieros mecánicos, eléctricos, de automatización y de software. Sus capacidades van mucho más allá de responder preguntas básicas: se encargan de todo, desde la configuración de PLC hasta el balanceo de línea y el diagnóstico de problemas.

Pero lo que realmente distingue a Rich Packing es su compromiso con Vídeos instructivos personalizados y específicos de la máquina Estos videos funcionan como un manual de instrucciones visual que abarca detalles operativos precisos como:

◉ Cómo conectar la energía (cableado trifásico, conexión a tierra, comprobaciones de voltaje)

◉ Cómo conectar líneas de aire o agua para máquinas pulidoras de cápsulas, sistemas de vacío o mostradores

◉ Cómo conectar varias máquinas en una línea completa de conteo o embotellado

◉ Cómo ensamblar unidades de alimentación, tolvas o componentes de llenado

◉ Cómo realizar la configuración de parámetros, la calibración y las pruebas

◉ Cómo solucionar los errores más comunes

Los operadores pueden pausar, reproducir, compartir y usar estos videos para capacitación interna, lo que los hace extremadamente valiosos para los equipos de producción en el extranjero, especialmente aquellos con una alta rotación de personal.

¿Y si el vídeo no resuelve totalmente el problema?

Rich Packing escala inmediatamente el problema a un

grupo especializado de ingeniería interna

—un equipo colaborativo que analiza casos complejos y aporta soluciones precisas.

Con estos recursos de ingeniería en su lugar, la capa final de soporte se vuelve aún más efectiva.

Para instalaciones a gran escala, como líneas de conteo de gomitas, líneas de llenado de botellas de múltiples carriles o sistemas de envasado de polvos de gran tamaño, algunos clientes prefieren asistencia en persona.

Cuando se solicita servicio en sitio, Rich Packing sigue una política clara y aceptada internacionalmente:

Coberturas para clientes pasajes de avión de ida y vuelta

Coberturas para clientes Tarifa de servicio de ingeniero (~USD 350/día)

Sin cargos adicionales ni ocultos

Esta claridad permite a los clientes planificar proyectos con confianza y mantener un control total sobre su estructura de costos.

Incluso cuando no se requiere servicio en sitio, el soporte remoto sigue siendo muy efectivo, especialmente para la instalación.

La puesta en marcha remota se ha convertido en una de las capacidades más valiosas de Rich Packing. Mediante video en tiempo real, fotos de alta resolución, diagnósticos digitales y una guía estructurada, los ingenieros acompañan a los clientes en cada paso del arranque de la máquina.

Por ejemplo:

Cuando una fábrica no puede entender Cómo conectar la línea de vacío de una llenadora de cápsulas Los ingenieros los guían visualmente.

Cuando un equipo no puede conseguir su línea de conteo de gomitas Para sincronizar con el transportador de botellas, el soporte remoto les ayuda a ajustar la sincronización del PLC.

Cuando los operadores no están seguros de cómo conectar fuentes de agua Para los sistemas de enfriamiento, los ingenieros proporcionan diagramas y direcciones en vivo.

Cuando un línea de llenado de polvo produce un peso inconsistente, la calibración se guía de forma remota.

En la mayoría de los casos, los clientes logran una producción de prueba estable dentro de 24–72 horas —sin esperar a que un ingeniero cruce las fronteras.

Y cuando surgen preguntas más adelante, la respuesta es sencilla: Contáctanos en cualquier momento .

La industria global de máquinas de envasado es cada vez más avanzada e interconectada, pero también más exigente. En este entorno, el servicio posventa, y no solo el rendimiento de la máquina, es lo que determina la estabilidad de la producción y la confianza del cliente.

Con:

|

Accesibilidad 24/7 |

|

Garantía de tres años |

|

Piezas de desgaste gratuitas durante un año |

|

Vídeos de instalación y formación personalizados |

|

Equipos profesionales de ingeniería |

|

Soporte transparente en sitio |

|

Puesta en servicio remota rápida |

Rich Packing Machinery garantiza que cada cliente, ya sea que opere una máquina llenadora de cápsulas, una línea de conteo de gomitas o una máquina envasadora de palitos de múltiples carriles, reciba soporte constante, confiable y profesional en cualquier parte del mundo.

Porque en el mercado global actual, las máquinas fuertes importan, pero un soporte fuerte importa aún más.