Semi-automatic capsule filling machines remain one of the most widely used solutions in capsule production, especially for small to medium-sized pharmaceutical manufacturers, nutraceutical producers, R&D laboratories, and companies operating with flexible or batch-based production lines. Compared with fully automatic systems, semi-automatic machines offer a balanced combination of investment cost, operational flexibility, and production efficiency, which is why they continue to represent a significant share of the market.

In daily operation, these machines are often used continuously and across different capsule sizes, formulations, and production schedules. As a result, their performance depends not only on proper operation, but also on consistent and correct maintenance practices. Many stability issues seen in real production are not caused by the machine itself, but by overlooked fundamentals such as power supply conditions, vacuum system care, and routine maintenance habits.

As a professional manufacturer of capsule filling equipment, we are frequently asked why similar semi-automatic capsule machines perform very differently in long-term use. Based on extensive manufacturing experience and feedback from production sites, the answer is clear: maintenance plays a far more critical role than most users expect.

In this article, we would like to share practical insights into how semi-automatic capsule filling machines should be maintained in real production environments. Rather than focusing on operating procedures, the following sections highlight three maintenance areas that have the greatest impact on machine stability, reliability, and service life.

For semi-automatic capsule filling machines used in different countries and regions, power supply requirements are not universal. Voltage levels, frequency standards, and power configurations vary widely across markets. When importing capsule filling machines from overseas, confirming electrical compatibility in advance is a fundamental but often underestimated step.

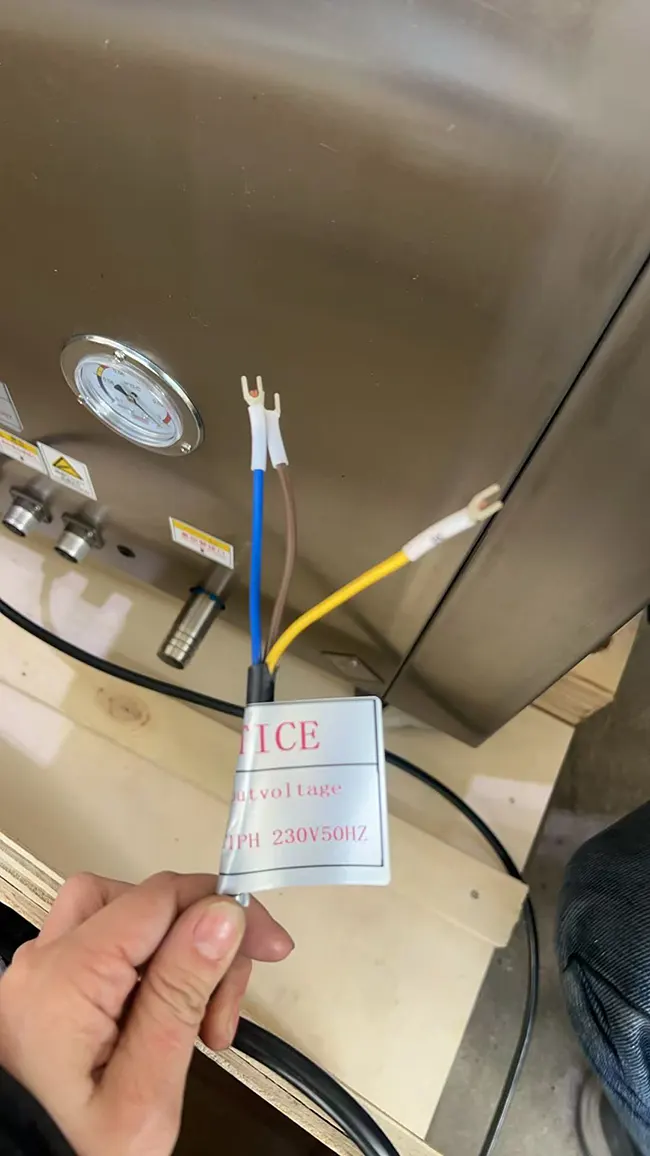

Before connecting the machine to the power supply for the first time, the actual on-site voltage should always be carefully checked and verified. Even when the equipment is correctly configured at the factory, differences in local power conditions, wiring errors, or installation assumptions may create discrepancies. In practice, we have seen many cases where components were damaged simply because voltage was not properly checked and confirmed before powering on.

For reassurance, we will put stickers on the power plug for operators to check.

In real production environments, connecting a machine to a power source that does not match its designed specifications may not cause immediate failure. However, this mismatch places continuous stress on motors, control circuits, and electrical components, gradually leading to unstable operation, abnormal behavior, or unexpected downtime. Many long-term electrical issues originate from improper power configuration during initial installation.

For semi-automatic capsule filling machines, the power and electrical system forms the foundation of all mechanical and pneumatic actions. Unlike purely mechanical equipment, these machines rely on coordinated operation between motors, control circuits, pneumatic components, and sensors. Even minor deviations in power supply—such as incorrect voltage, unstable frequency, or improper grounding—can have cumulative effects on machine stability, control accuracy, and component lifespan.

Because electrical systems operate continuously throughout production, verifying voltage and electrical compatibility should be treated as a standard installation and maintenance practice, particularly for cross-border equipment deliveries. Proper electrical setup ensures not only safe operation, but also long-term reliability and predictable performance.

We customize semi-automatic capsule filling machines to meet the distinct voltage and frequency requirements of the destination market. Common configurations include single-phase or three-phase power, with voltage options such as 110 V, 220 V, 380 V, or 400 V, at either 50 Hz or 60 Hz. These parameters are fixed during manufacturing and must match the actual on-site power supply.

Before installation, the incoming power supply should be measured and confirmed against the machine’s nameplate and electrical documentation. This includes not only nominal voltage, but also phase type and frequency. In real production environments, mismatches often occur due to assumptions—such as assuming all three-phase supplies are identical, or assuming factory wiring matches local standards.

Unstable or incorrect voltage may not immediately prevent the machine from running, but it directly affects components such as motors, inverters, and power modules. Typical early signs include abnormal motor temperature, inconsistent speed response, or intermittent alarms. Over time, continued operation under incorrect voltage conditions significantly increases the risk of component damage and unplanned downtime.

Proper grounding is a mandatory requirement for semi-automatic capsule filling machines, serving both operational stability and personnel safety. The grounding conductor must be securely connected to the designated grounding terminal on the machine and bonded to a reliable earth ground at the installation site.

Inadequate grounding can lead to unstable control signals, sensor miscommunication, and increased electrical noise within the control system. These issues often appear as irregular machine behavior that is difficult to trace to a single mechanical cause. From a safety perspective, missing or poor grounding also increases the risk of electric shock during operation or maintenance.

Grounding connections should be inspected during installation and periodically thereafter. Loose grounding terminals, corrosion, or damaged grounding cables can compromise system stability even if the rest of the electrical installation appears normal.

Electrical wiring quality has a direct impact on the long-term reliability of a semi-automatic capsule filling machine. Many avoidable electrical failures originate from improper wiring practices during installation. For risk mitigation and consistent operational stability, the following guidelines must be strictly :

Qualified electrical installation

Only licensed electricians who are familiar with industrial-grade equipment are authorized to conduct all wiring operations. Electrical wiring connections must adhere to local electrical standards as well as the machine’s technical specifications.

Power-off confirmation before wiring

The main power supply must be fully disconnected before any wiring or inspection work. This prevents accidental electric shock and protects electrical components during installation.

Correct cable sizing and secure connections

Power cables should be sized according to the machine’s rated current. All terminals must be securely fastened to avoid loosening during operation, which can cause localized heating, voltage drop, or intermittent faults.

Proper insulation and protection

After wiring is completed, exposed conductors should be properly insulated using suitable materials such as insulation tape or heat-shrink tubing. This measure serves to reduce the potential for short circuits and damage to the surrounding environment.

Initial no-load power-on check

Before starting production, the machine should be powered on without load to verify that electrical indicators, control circuits, and basic functions operate normally. Any abnormal noise, smell, or alarm should be investigated immediately before proceeding.

Integrity of protective enclosures

For safety purposes, electrical cabinets and control panels are required to remain securely closed during operation. Interlock protection devices should remain functional to prevent accidental contact with live components and reduce dust ingress into the electrical system.

In a semi-automatic capsule filling machine, the vacuum system plays a far more important role than many users initially realize. While it operates quietly in the background, its performance directly affects capsule separation accuracy, production stability, and final yield quality.

During capsule orientation and separation, the vacuum system must provide consistent and controlled negative pressure. If vacuum performance fluctuates or degrades over time, issues such as flying caps, incomplete separation, or unstable capsule positioning may begin to appear. These problems are often mistaken for mechanical or capsule-quality issues, when in fact the vacuum system is the underlying cause.

For this reason, the choice of vacuum pump and related electrical components is critical. We use components from internationally recognized brands such as Siemens and Schneider Electric not only for their stable performance and proven reliability, but also for practical reasons that matter in real production environments. When replacement or servicing is required, standardized components can be sourced locally in most countries, significantly reducing downtime caused by long lead times or special-order parts. In the long run, this approach helps customers maintain production continuity and respond more efficiently to unexpected maintenance needs.

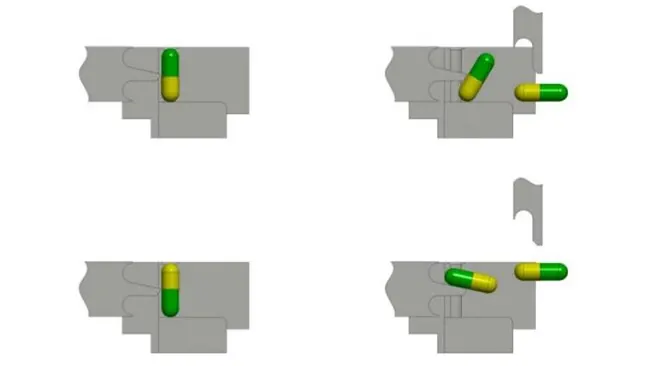

During capsule separation, the vacuum system must maintain a stable and appropriate negative pressure. Vacuum that is too strong or too weak will both result in visible production problems.

When vacuum pressure is too high, capsule caps may be pulled away too aggressively, leading to flying caps or surface damage. When vacuum pressure is insufficient, capsule bodies and caps may fail to separate completely, resulting in unstable positioning or incomplete filling preparation. In practice, these symptoms are frequently attributed to capsule quality, while the actual cause lies in improper vacuum adjustment.

A key point is that vacuum performance should be evaluated by separation behavior, not by pressure value alone. Stable capsule separation without flying caps or missed separation is the most reliable indicator that vacuum is operating within the correct range.

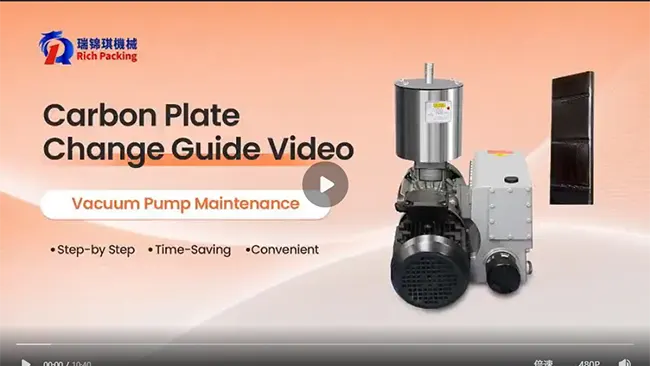

The vacuum pump is the heart of the vacuum system, and its internal condition directly affects vacuum stability. Vacuum pump oil maintenance ranks as a common but often undervalued consideration.

Vacuum pump oil fulfills two key roles: it works as a lubricant and serves as a sealing medium inside the pump. If the oil level is too low, internal friction increases and vacuum efficiency drops. If the oil becomes contaminated, emulsified, or degraded, internal sealing performance deteriorates, resulting in unstable negative pressure even when the pump appears to be running normally.

In real production environments, weakened vacuum caused by poor oil condition often manifests as intermittent separation issues rather than complete pump failure. This makes oil inspection a critical diagnostic step whenever capsule separation becomes inconsistent.

Feel free to contact us for tutorial video showing how to change the carbon vanes.

Fine powder and capsule fragments are unavoidable in capsule filling operations. Without proper filtration, these contaminants enter the vacuum system and gradually reduce performance.

Filters installed in the vacuum line are designed to intercept powder residue and capsule debris before they reach the pump. As filters become clogged, airflow resistance increases, reducing effective vacuum pressure at the separation point. This can lead to unstable separation even if the pump itself is in good mechanical condition.

In addition to filtration, vacuum line integrity is equally important. Tiny leaks occurring at hose interfaces or due to aging seals may not be readily observable, but they have a significant negative impact on vacuum efficiency. Over time, these minor losses accumulate and result in noticeable production instability.

Maintaining clean filters and airtight vacuum lines is therefore essential for preserving consistent vacuum performance and long-term system reliability.

Daily maintenance is often viewed as a routine task, but in reality, it is one of the most decisive factors in long-term machine performance. In semi-automatic capsule filling machines, many mechanical and pneumatic components operate in close proximity to fine powders and moving parts. Without consistent daily care, minor issues can gradually accumulate and lead to unstable operation.

Unlike major repairs, daily maintenance does not require complex tools or long downtime. Instead, it relies on disciplined habits that keep the machine in a stable and predictable condition throughout its service life.

Cleaning a semi-automatic capsule machine is not primarily about keeping the equipment visually clean. Powder residue left on contact surfaces, guide rails, or transmission components can increase friction, interfere with smooth motion, and affect component alignment over time.

Regular cleaning helps prevent powder buildup in hidden areas where it may absorb moisture, harden, or migrate into mechanical interfaces. By maintaining clean working surfaces and moving parts, operators reduce the risk of gradual performance degradation and unexpected interruptions during production.

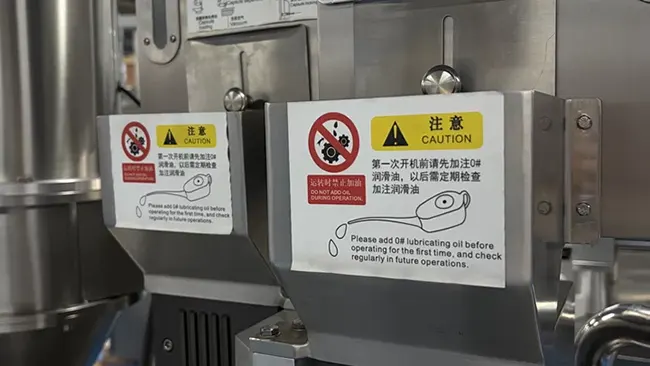

Lubrication plays a critical role in reducing wear and maintaining smooth mechanical motion, but it must be applied correctly. Different components within a semi-automatic capsule filling machine have different lubrication requirements, and improper lubrication can be as harmful as neglect.

Over-lubrication may attract powder and dust, creating abrasive buildup, while using unsuitable lubricants can contaminate product-contact areas or degrade seals. Applying the right lubricant, in the right amount, at the right interval helps protect components and preserve stable machine behavior.

Daily maintenance is also the most effective opportunity to detect early signs of wear or abnormal conditions. Simple inspections—such as checking fasteners, observing motion smoothness, and listening for unusual noise—often reveal issues before they escalate into faults.

Establishing consistent daily and periodic maintenance routines allows operators to identify deviations early, schedule corrective actions proactively, and minimize unplanned downtime. These practices, when maintained over time, will boost production process reliability and extend the machine’s service longevity.

Maintaining a semi-automatic capsule filler machine is not about performing occasional fixes when problems appear. It is about preserving the stability of fundamental systems that support daily production. Power supply integrity, vacuum system performance, and consistent daily maintenance together determine whether a machine operates predictably or gradually becomes a source of uncertainty.

In real manufacturing environments, most operational issues can be traced back to overlooked basics rather than design limitations. When these fundamentals are properly maintained, semi-automatic capsule machines deliver reliable performance, stable output quality, and a more controlled production process.

By treating maintenance as an integral part of production rather than an additional burden, manufacturers can reduce downtime, extend equipment service life, and create a more efficient and dependable working environment. Over time, disciplined maintenance practices prove to be one of the most practical investments in long-term operational stability.