Máquina de embalaje blíster Es una máquina envasadora automatizada ampliamente utilizada en las industrias farmacéutica, alimentaria, electrónica y de bienes de consumo. Su función principal es encapsular el producto en un blíster transparente de plástico o aluminio para protegerlo y ofrecer un envasado práctico. Incluye múltiples etapas de trabajo, como el termoformado, el llenado de múltiples tipos de material (tabletas/cápsulas/líquidos/sólidos, etc.), el termosellado, el estampado por indentación, la tracción y el troquelado. Hoy les explicaré principalmente el funcionamiento y el proceso de la máquina envasadora plana de aluminio y plástico.

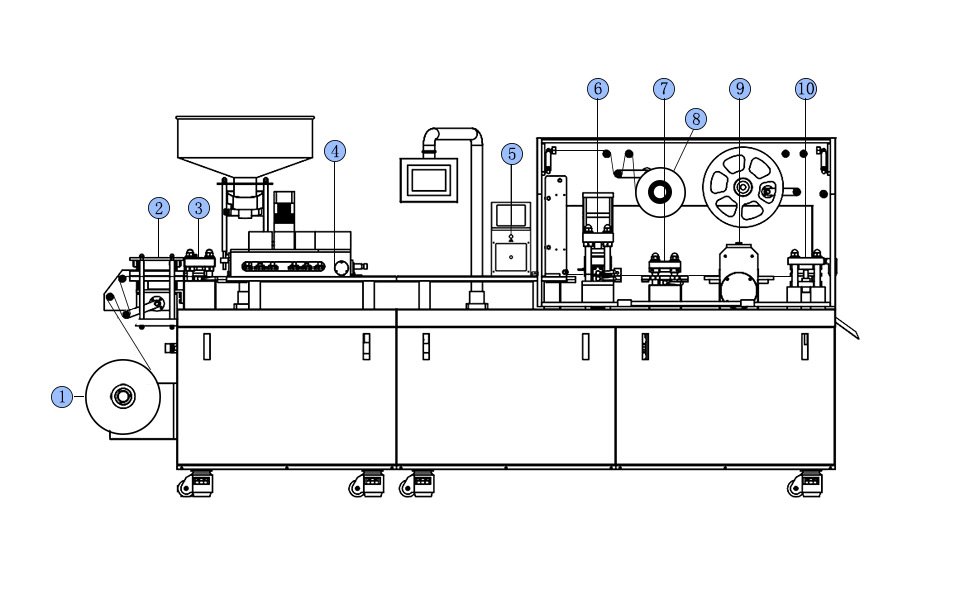

Introducción de cada estación de la máquina envasadora de aluminio y plástico de tipo plano:

Introducción de cada estación de la máquina envasadora de aluminio y plástico de tipo plano:

1. Material de conformado; 2. Calor; 3. Moldeo; 4. Relleno de material; 5. Inspección de chatarra; 6. Sellado térmico; 7. Indentación; 8. Película de aluminio posterior; 9. Tracción; 10. Troquelado

Preparación y carga de materiales: En primer lugar, los operarios deben preparar los materiales de embalaje y los productos a envasar. Los materiales de embalaje suelen incluir láminas de plástico (como PVC, PET o PVDC) y papel de aluminio como placa base. La lámina de plástico se carga en el sistema de alimentación de la máquina, mientras que el papel de aluminio se instala en el dispositivo de desenrollado correspondiente. El producto a envasar debe introducirse en un sistema de alimentación especialmente diseñado para su forma y tamaño.

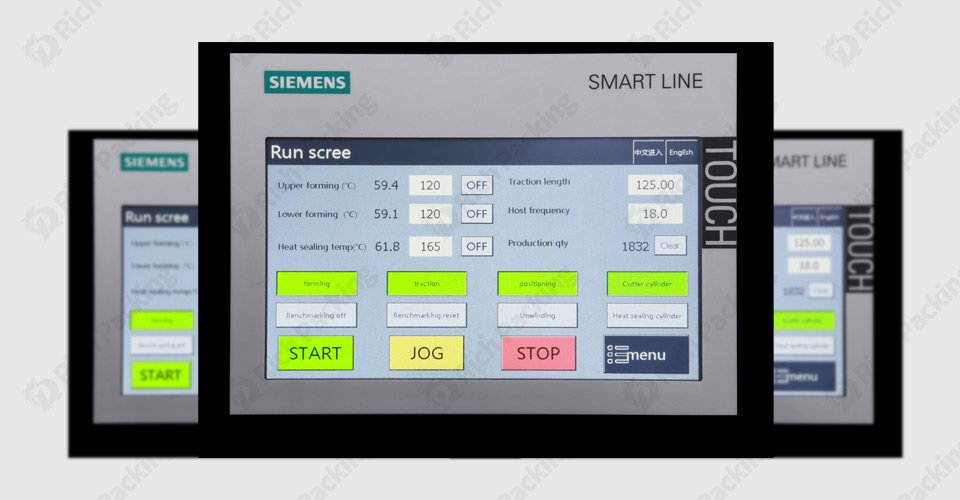

2. Precalentamiento de la lámina de plástico: La estación de calentamiento de la blíster precalentará la lámina de plástico. Este paso es fundamental, ya que permite que el plástico alcance la temperatura adecuada para ablandarlo y hacerlo más plástico para el posterior proceso de moldeo. El control de la temperatura de precalentamiento debe ser preciso, ya que los diferentes tipos de plásticos tienen diferentes temperaturas de ablandamiento. El operador puede ajustar la temperatura mediante el panel de control para garantizar un precalentamiento óptimo.

3. Moldeo de láminas de plástico: La lámina de plástico precalentada ingresa a la estación de moldeo. Aquí, la máquina utiliza tecnología de presión y aire comprimido para prensarla en la forma deseada del blíster. El molde se personaliza según el tamaño y la forma específicos del producto, y se pueden fabricar diversos moldes para blíster según las necesidades de forma de cada producto. Durante el proceso de moldeo, el plástico, fácilmente ablandado, se sopla mediante el sistema de aire comprimido, lo que garantiza que se ajuste completamente a la superficie del molde y forme una forma de blíster precisa.

4. Llenado del producto: Tras el moldeado, la tapa de burbuja se traslada a la estación de llenado de material. En esta etapa, la blíster coloca con precisión el producto en cada blíster mediante un robot de precisión o un sistema de alimentación de disco vibratorio (algunos materiales especiales también pueden colocarse manualmente). Para garantizar la calidad y la eficiencia del envasado, las máquinas suelen estar equipadas con un sistema de inspección visual que supervisa la correcta colocación e integridad del producto. Si se detecta alguna anomalía, el sistema emite una alerta o retira automáticamente el producto no apto para evitar que llegue a manos de los consumidores.

5. Sello de papel de aluminio: Tras el llenado del producto, el blíster se traslada a la estación de sellado térmico. Aquí, el papel de aluminio se coloca con precisión sobre el blíster. La prensa en caliente aplica presión y calor a toda la superficie, sellando el papel firmemente sobre el blíster. Este proceso requiere un control preciso de la temperatura, la presión y el tiempo para garantizar un sellado perfecto, evitar la entrada de aire y humedad al interior del envase y mantener la superficie del papel de aluminio plana y con buena apariencia tras el sellado térmico.

6. Enfriamiento: El cartón sellado de aluminio y plástico debe enfriarse inmediatamente. Las estaciones de enfriamiento suelen utilizar aire frío o placas de enfriamiento para reducir rápidamente la temperatura del paquete. Esto no solo mejora la resistencia del paquete, sino que también previene la deformación o daños del producto causados por el calor, lo que afecta la integridad y la estética de la garantía.

7. Codificación y etiquetado: Tras el sellado térmico, muchas blísteres también incorporan sistemas de codificación o indentación. Estos sistemas permiten imprimir información importante, como números de lote, fechas de producción y fechas de caducidad, en el envase. Este paso es esencial tanto para la trazabilidad del producto como para su comercialización.

8. Corte y conformación: El producto terminado ingresa a la estación de troquelado tras el termosellado o la codificación. Aquí, la blísteradora corta la cinta en blísteres individuales o múltiples, según el tamaño y la forma predefinidos. Las herramientas de corte suelen utilizar troqueles de precisión, que permiten troquelar y cortar sin dañar el contenido del envase.

9. Control de calidad: En la última etapa del proceso de envasado, la blíster suele realizar también un control de calidad final. Este puede incluir pruebas de peso, comprobaciones de la integridad del sellado, comprobaciones de la apariencia, etc. Las máquinas avanzadas pueden incluso estar equipadas con sistemas de inspección por rayos X para comprobar la integridad y la correcta conservación de los productos dentro del envase. Los envases de baja calidad se eliminan automáticamente, garantizando así que solo los productos de alta calidad pasen a la siguiente etapa.

10. Recogida y embalaje: Los productos terminados calificados se recogen finalmente en el sistema de descarga. Según las necesidades, estos paquetes pueden ir directamente a la máquina envasadora de cartón conectada para su posterior envasado o recogerse manualmente para su posterior procesamiento.

Todo el proceso de operación de la máquina blíster está altamente automatizado, pero requiere la supervisión y el ajuste por parte de operadores cualificados. Estos deben revisar periódicamente las distintas partes de la máquina para garantizar su correcto funcionamiento y ajustar los parámetros según las necesidades de los diferentes productos.

1. Producción de alta eficiencia: La moderna máquina envasadora de blíster puede envasar a una velocidad muy rápida, y la máquina de plástico y aluminio con placa de rodillo de alta velocidad puede incluso alcanzar la velocidad de producción de cientos de miles de paquetes por minuto.

2. Flexibilidad: Cambiando el molde y ajustando los parámetros, se puede utilizar la misma máquina para envasar una variedad de productos de diferentes tamaños y formas.

3. Control preciso: El avanzado sistema de control permite al operador ajustar con precisión los parámetros de cada estación de trabajo, como temperatura, presión y tiempo, para adaptarse a las necesidades de diferentes materiales y productos.

4. Seguridad: La máquina envasadora de blíster generalmente está equipada con múltiples dispositivos de seguridad, como botón de parada de emergencia, bloqueo de puerta de seguridad, etc., para proteger la seguridad del operador.

5. Limpieza: Especialmente en la industria farmacéutica, el diseño de la máquina envasadora de blíster debe cumplir estrictos estándares de limpieza, ser fácil de limpiar y mantener, para garantizar la higiene del entorno de producción.

6. Registro y análisis de datos: Muchas máquinas modernas de envasado blíster están equipadas con sistemas de registro de datos, que pueden monitorear y registrar los parámetros de producción en tiempo real, contribuyendo al control de calidad y la optimización de la producción.

7. Monitoreo y mantenimiento remoto: Algunos modelos de alta gama incluso admiten funciones de diagnóstico y monitoreo remoto, lo que permite al fabricante o al personal de mantenimiento acceder de forma remota a la máquina para solucionar problemas y realizar actualizaciones de software.

En resumen, la máquina blíster es un equipo de envasado complejo y sofisticado que, mediante una serie de pasos cuidadosamente diseñados, envasa el producto de forma segura e higiénica en blísters de aluminio y plástico. Gracias al continuo avance tecnológico, la eficiencia, la precisión y la funcionalidad de la máquina blíster mejoran constantemente, ofreciendo soluciones de envasado eficientes y de alta calidad para diversas industrias.