Máquina prensadora de tabletas Es un equipo de producción esencial para compañías farmacéuticas, de productos sanitarios, químicas y otras. Se utiliza principalmente para prensar materiales en polvo o granulares en comprimidos monocapa o multicapa con tamaño, forma y peso uniformes mediante diferentes máquinas de proceso o matrices de estampado. Este artículo ofrece una descripción detallada de las prensas de comprimidos, incluyendo su historia, tipos, principios de funcionamiento, componentes y aplicaciones.

El proceso de fabricación de comprimidos implica varias etapas críticas para garantizar una producción de alta calidad. Inicialmente, los ingredientes farmacéuticos activos (API) y los excipientes se pesan y mezclan con precisión. Esta mezcla se granula para mejorar la fluidez y la compresibilidad, seguida de un secado si se utiliza granulación húmeda. A continuación, los gránulos se dimensionan para uniformizarlos y se mezclan con excipientes adicionales como lubricantes y desintegrantes. La etapa principal es la compresión, donde los gránulos mezclados se introducen en una prensa de comprimidos y se comprimen en comprimidos bajo presión controlada para garantizar una densidad y dureza uniformes. Finalmente, los comprimidos pueden recubrirse para mejorar su aspecto, sabor y estabilidad antes de envasarlos, protegiéndolos de los factores ambientales y garantizando su vida útil.

La historia de las prensas de comprimidos se remonta al siglo XIX. Su evolución está impulsada por la necesidad de la industria farmacéutica de lograr eficiencia en la producción de comprimidos, consistencia en el tamaño de los comprimidos y estabilidad de calidad, lo que impulsa la innovación y la mejora continua de la tecnología.

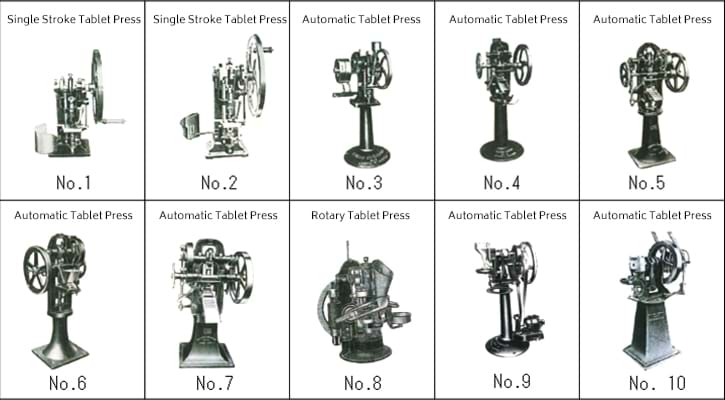

1. Primeros comienzos: El concepto de compresión de tabletas surgió en el siglo XIX. La primera prensa manual de tabletas era un dispositivo sencillo que utilizaba un solo punzón para comprimir el polvo y formar tabletas. Estas primeras máquinas requerían mucha mano de obra y tenían una capacidad de producción limitada.

2. Introducción de la prensa rotatoria de tabletas: En 1872, una compañía farmacéutica estadounidense desarrolló una de las primeras prensas rotativas para tabletas. Esta innovación marcó un avance significativo en la fabricación de tabletas. La prensa rotativa para tabletas permitió la producción continua, aumentando significativamente la productividad y la eficiencia de la producción de tabletas.

3. Avances del siglo XX: El siglo XX presenció numerosos avances en la tecnología de las prensas de comprimidos. La introducción de motores eléctricos y la automatización mejoraron aún más la eficiencia y la precisión de las prensas. Durante este período, se desarrollaron diversos tipos de prensas, incluyendo prensas rotativas de un solo punzón y multiestación, para satisfacer la creciente demanda de la industria farmacéutica.

4. Era Moderna: Con el desarrollo de la ciencia y la tecnología en la era moderna, Prensa de tabletas de alta velocidad La tecnología también ha experimentado cambios revolucionarios. Han evolucionado desde simples estructuras mecánicas hasta contar con funciones digitales avanzadas, como la visualización digital del proceso de producción controlada por computadora, sistemas de alimentación automática y la monitorización del estado de la producción a presión en tiempo real. Estos avances tecnológicos han permitido a los fabricantes de tabletas mejorar aún más su eficiencia de producción, satisfacer la creciente demanda del mercado y mantener la calidad de las tabletas producidas.

Según los diferentes requisitos de aplicación y escalas de producción, las prensas de tabletas se dividen principalmente en los siguientes tipos:

1. Prensa de tabletas de un solo punzón: Las prensas de comprimidos de un solo punzón utilizan un punzón y una matriz para el tableteado. El punzón se mueve entre las matrices superior e inferior para prensar el polvo o los gránulos y convertirlos en comprimidos.

2. Prensa rotatoria de tabletas: La tableteadora rotativa consta de un plato giratorio y múltiples punzones. Al girar el plato giratorio, los punzones entran en la zona de tableteado para prensar el polvo o los gránulos y convertirlos en tabletas.

3. Prensa de tabletas de alta velocidad: La tableteadora de alta velocidad es una versión mejorada de la tableteadora rotativa, diseñada para la producción industrial de gran volumen. Su avanzado sistema de control permite supervisar y ajustar los parámetros de tableteado en tiempo real para garantizar la calidad y consistencia de cada tableta.

4. Prensa de tabletas multicapa: Una prensa de comprimidos multicapa permite comprimir varias capas en un mismo comprimido, cada una de las cuales puede contener diferentes principios activos o excipientes. Este equipo es adecuado para la producción de comprimidos funcionales que requieren una estructura multicapa, como comprimidos de liberación sostenida, comprimidos de liberación controlada, etc.

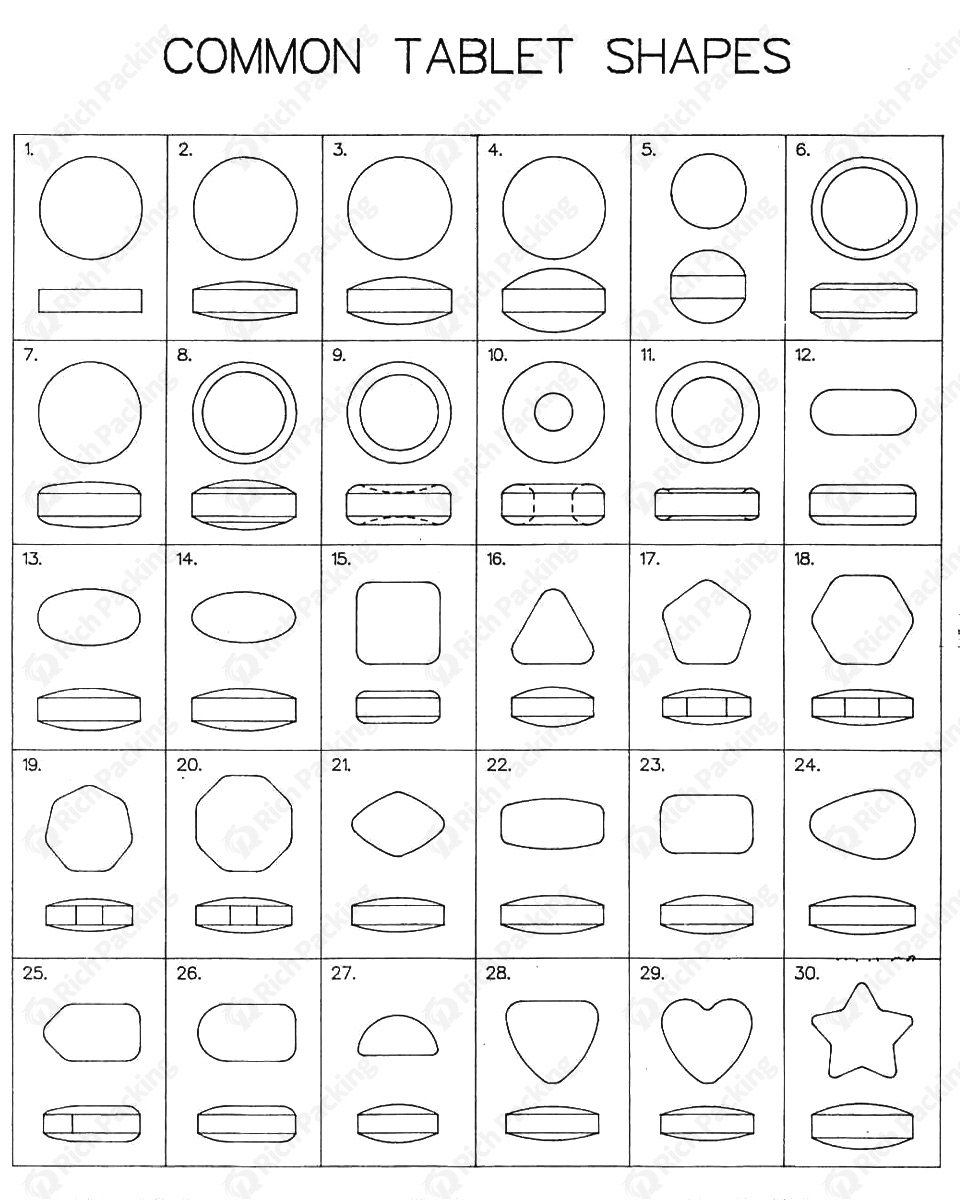

5. Prensa de tabletas para usos especiales: Una prensa de comprimidos para usos específicos es un dispositivo diseñado para satisfacer necesidades de producción específicas, generalmente con módulos y diseños funcionales únicos. Por ejemplo, una prensa de comprimidos para la producción de comprimidos efervescentes debe estar equipada con un sistema a prueba de humedad, mientras que una prensa de comprimidos para la producción de comprimidos con formas especiales requiere un molde personalizado.

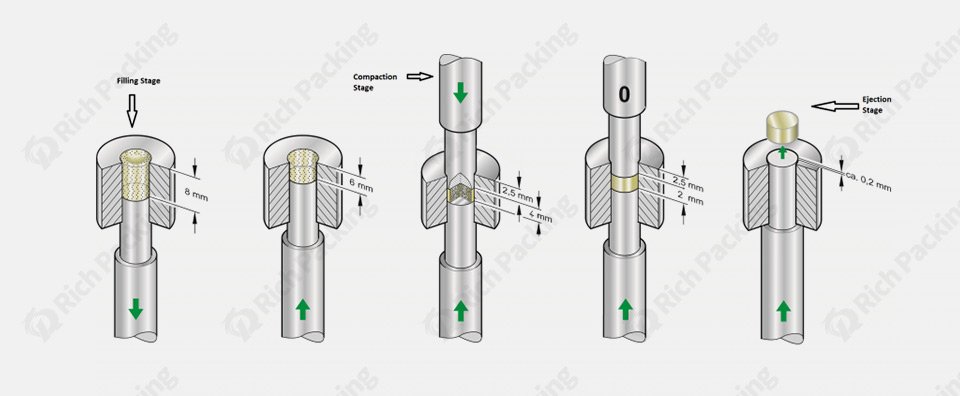

Las prensas de comprimidos convierten materiales en polvo o granulares en comprimidos sólidos mediante una serie de pasos bien coordinados. A continuación, se detalla la descripción. Desglose del proceso:

1. Alimentación de materias primas

El proceso comienza con la introducción de la materia prima en la cavidad de la matriz de la máquina. Esta tarea suele realizarse mediante un mecanismo de alimentación diseñado para mantener un flujo de material constante y uniforme. Para materiales con alta adherencia, se puede emplear un alimentador forzado para facilitar una alimentación fluida.

2. Llenado de la cavidad del molde

Una vez introducidas las materias primas, estas llenan la cavidad del molde. La cantidad de material que se introduce en la cavidad del molde se controla mediante el punzón inferior, que se ajusta a una altura específica para permitir la entrada del volumen deseado. Un llenado preciso es crucial para garantizar un peso y una consistencia uniformes de las tabletas.

3. Compresión

La etapa de compresión consta de dos punzones: el superior y el inferior. Así es como funciona:

Punzón superior: la rueda de presión del punzón superior se presiona hacia abajo en la cavidad de la matriz central y coopera con el punzón inferior para extruir y dar forma al material en polvo.

Punzón inferior: el punzón inferior sostiene el material desde abajo y también puede moverse ligeramente hacia arriba para ayudar en la compresión.

La presión aplicada por los punzones compacta el polvo o los gránulos formando una tableta sólida y cohesiva. La presión se controla cuidadosamente para garantizar que la tableta no quede ni demasiado dura ni demasiado blanda.

4. Eyección

Una vez finalizada la formación de la tableta, el punzón superior y el punzón inferior vuelven a sus posiciones según la pista, y el punzón inferior empuja la tableta formada fuera de la cavidad de la matriz hacia el puerto de descarga a través de la pista inferior. Este paso debe ser suave para evitar cualquier daño a la tableta.

5. Repetir ciclo

La prensa de comprimidos opera en un ciclo continuo, repitiendo los pasos de alimentación, llenado, compresión y expulsión. Esto permite una producción de comprimidos a alta velocidad. Las máquinas avanzadas pueden producir miles de comprimidos por minuto, manteniendo una calidad y uniformidad constantes.

6. Control de calidad

Las prensas de comprimidos de última generación están equipadas con diversos sensores digitales y sistemas de control analítico que permiten monitorear en tiempo real diversos parámetros, como la presión del molde, el grosor de la tableta y el peso del polvo de relleno. Mediante un control digital sistemático, se garantiza que la producción de cada tableta cumpla con las especificaciones establecidas y se garantiza la calidad y la eficiencia de la producción.

Los componentes clave de las prensas de comprimidos incluyen la tolva, el sistema de alimentación, la cavidad del troquel, los punzones superior e inferior, las guías de levas, la torreta, el mecanismo de expulsión y el sistema de control. Cada componente desempeña un papel vital para garantizar la producción eficiente y consistente de comprimidos de alta calidad. Comprender estos componentes y sus funciones es esencial para optimizar los procesos de fabricación de comprimidos.

1. Tolva

La tolva es el punto de partida de la prensa de tabletas. Contiene el polvo o los gránulos crudos y los alimenta a la máquina. Está diseñada para garantizar un flujo constante y controlado de material hacia el sistema de alimentación, evitando obstrucciones y garantizando la uniformidad en la producción de tabletas.

2. Sistema de alimentación

El sistema de alimentación transfiere el material desde la tolva hasta la cavidad del molde. Generalmente, consta de paletas o un mecanismo giratorio que distribuye uniformemente el material en los moldes. El sistema de alimentación garantiza que cada cavidad del molde reciba la cantidad correcta de material, esencial para producir tabletas con un peso y una densidad uniformes.

3. Cavidad de la matriz

La cavidad del molde es un espacio hueco dentro de la mesa donde se forma la tableta. El tamaño y la forma de la cavidad determinan el tamaño y la forma de la tableta final. El llenado preciso de la cavidad del molde es crucial para mantener la uniformidad y la calidad de la tableta.

4. Golpes superiores e inferiores

Los punzones son los componentes principales encargados de comprimir el material en tabletas. Una prensa de tabletas cuenta con dos punzones:

Punzón superior: desciende a la cavidad de la matriz para aplicar presión sobre el material.

Punzón inferior: sostiene el material desde abajo y también puede moverse levemente para ayudar en el proceso de compresión.

Los punzones deben estar alineados y mantenidos con precisión para garantizar una calidad constante de la tableta y evitar el desgaste de la máquina.

5. Pistas de leva

Las guías de leva guían el movimiento de los punzones superior e inferior. Controlan el movimiento vertical de los punzones, garantizando su sincronización. Las guías de leva están diseñadas para proporcionar la presión y la sincronización adecuadas en cada etapa del proceso de formación de tabletas.

6. Torreta o mesa giratoria

La torreta, o mesa giratoria, alberga múltiples juegos de matrices y punzones. Gira para posicionar cada cavidad de la matriz y sus punzones correspondientes para el llenado, la compresión y la expulsión. La rotación continua de la torreta permite la producción de tabletas a alta velocidad.

7. Mecanismo de eyección

El mecanismo de expulsión se encarga de retirar las tabletas formadas de la cavidad de la matriz. Tras la compresión, el punzón superior se retrae y el punzón inferior se eleva para expulsar la tableta de la matriz. La tableta expulsada se dirige a un conducto de descarga, donde se recoge para su posterior procesamiento o envasado.

8. Sistema de control

Las prensas de comprimidos modernas están equipadas con sistemas de control avanzados que monitorean y ajustan diversos parámetros, como la fuerza de compresión, el grosor de la tableta y la velocidad de producción. Estos sistemas garantizan que cada tableta cumpla con las especificaciones y los estándares de calidad requeridos. Además, proporcionan datos y retroalimentación en tiempo real, lo que permite a los operadores realizar los ajustes necesarios rápidamente.

Las máquinas prensadoras de tabletas se utilizan en diversas industrias para diferentes aplicaciones:

1. Industria farmacéutica: Las prensas de comprimidos se utilizan principalmente para producir comprimidos medicinales, como vitaminas, antibióticos y analgésicos. Garantizan una dosificación precisa y una calidad constante, aspectos cruciales para la seguridad y la eficacia del paciente.

2. Industria nutracéutica: Las empresas nutracéuticas utilizan prensas de tabletas para fabricar suplementos dietéticos, como multivitaminas, minerales y extractos de hierbas. Estas tabletas están diseñadas para brindar beneficios para la salud y suelen comercializarse como productos de venta libre.

3. Industria alimentaria: En la industria alimentaria, las prensas de tabletas se utilizan para producir productos alimenticios comprimidos, como tabletas efervescentes, cubitos de caldo y productos de confitería. Estos productos están diseñados para su comodidad y facilidad de uso.

4. Industria química: Las prensas de tabletas se utilizan para producir diversos comprimidos químicos, como agentes de limpieza, fertilizantes y pesticidas. Estas tabletas están diseñadas para una liberación controlada y una aplicación precisa.

5. Industria cosmética: En la industria cosmética, las prensas de tabletas se utilizan para producir polvos compactos, rubores y otros productos de maquillaje prensados. Estos productos están diseñados para facilitar su aplicación y portabilidad.

Las prensas de comprimidos son equipos vitales en las industrias farmacéutica, nutracéutica, alimentaria, química y cosmética. Han evolucionado significativamente a lo largo de los años, desde simples prensas manuales hasta sofisticadas máquinas automatizadas capaces de producir a gran escala y a alta velocidad. Con los avances tecnológicos, las prensas de comprimidos siguen mejorando en eficiencia, precisión y versatilidad, satisfaciendo las diversas necesidades de diversas industrias. A medida que crece la demanda de comprimidos de alta calidad, las prensas de comprimidos se mantendrán a la vanguardia de la fabricación de comprimidos, impulsando la innovación y la excelencia en el proceso de producción.

Somos un fabricante que lleva mucho tiempo suministrando maquinaria farmacéutica y de envasado a empresas de la lista Fortune 500. Si necesita comprar una prensa de comprimidos, por favor... Contáctanos .